What is a GMA Pallet?

A GMA pallet is constructed to meet the standardized guidelines for food industry pallets developed by the Grocery Manufacturers Association (GMA).

The Grocery Manufacturers Association — recently rebranded as the Consumer Brands Association (CBA) — established these pallet guidelines as a way to streamline food industry transportation, storage and distribution.

Pallets can be found anywhere food and beverages are handled, including grocery stores, distribution centers and manufacturing plants. When the pallets used conform to GMA pallet specification guidelines, it ensures fast and easy movement of goods.

What Are the GMA’s Pallet Specifications?

Specifications for GMA pallets include elements like load-bearing capacity, transportability, GMA pallet dimensions and board configuration. Standard GMA pallet specifications include:

- An overall footprint of 40″ by 48″.

- A minimum load-bearing capacity of 2,500 pounds.

- Two notches on each side for four-way forklift entry.

- Top and bottom deck boards that are 5/8″ thick.

- A top board configuration of a 5 1/2″ wide board on each end and five 3 1/2″ wide boards in the center.

- A bottom board configuration of a 5 1/2″ wide board on each end and three 3 1/2″ wide boards between the notches.

GMA pallets account for an estimated 30% of the pallet marketplace. As the food and beverage industry continues to develop, it is more important than ever to transport and handle products as quickly and cost-effectively as possible.

Choosing GMA pallets reduces the time and expenses that could arise from shipping and storing products on nonstandardized pallets.

Browse Our Plastic Pallet Selection

Other Recognized Standard Pallet Sizes

The International Organization for Standardization (ISO) recognizes GMA pallets as one of six standard pallet types.

Though GMA standardized pallets are most commonly used for North American enterprises, the remaining five ISO standard pallet types are frequently used worldwide.

It’s important to note that while North American standard pallet dimensions are measured in inches, most countries use the metric system for their measurements. Their pallets are measured in millimeters. Some regional standards are as follows:

- North America: In addition to standard GMA pallets, North America also uses 42″ by 42″ pallets when shipping internationally to Europe and Asia.

- Asia: Industries in Asia use three ISO-recognized pallet sizes — 42″ by 42″, 1000 millimeters by 1200 millimeters and 1100 millimeters by 1100 millimeters.

- Europe: Like Asia, Europe uses 42″ by 42″ and 1000 millimeters by 1200 millimeters. They also use a more rectangular 800-millimeter by 1200-millimeter standard pallet.

- Australia: Australian industries use standardized 1165-millimeter by 1165-millimeter pallets.

What Are GMA Pallet Grades?

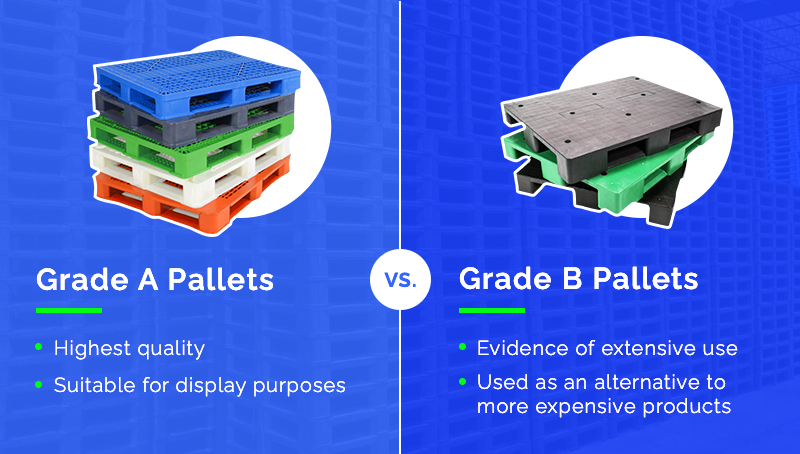

Pallets that are not brand new are subject to classification according to GMA pallet grading standards. GMA classifies recycled pallets into two groups they call Grade A and Grade B. Some manufacturers also refer to these grades as #1 and #2.

Within these grades, pallets are often subdivided into smaller grade categories for more comprehensive evaluation. GMA’s standard A and B grades, as well as any subdivisions, are based on features such as general appearance, structural integrity, compliance with GMA pallet specs and the extent of any repairs performed.

Here’s a brief look at what these different GMA grade classifications entail.

Grade A Pallets

GMA’s Grade A pallet classification encompasses the highest quality recycled pallets. These pallets are in exceptional condition, with no stringer repairs and only minor discoloration or superficial imperfections.

GMA Grade A pallets are considered suitable for display purposes in grocery stores or markets where they will come in direct contact with customers.

Subdivisions within the category have been established to distinguish between the most like-new and those with minor imperfections.

1. Premium Grade A Pallets

For a pallet to be considered Premium A, it has to meet all the standard specifications for GMA, including size, transportability and board configuration. These pallets feature bright colors and minimal superficial damage like scrapes and splinters.

Often appearing good-as-new, Premium A pallets — also known as 1A or food-grade pallets — are ideal for products being delivered and displayed for grocery store customers.

Premium Grade A pallets are traditionally composed of high-quality hardwood materials, but because these pallets are in such high demand, the standards for compositional materials have changed a bit. Many Premium GMA Grade A pallets are now made of pine or eco-friendly recyclable plastic.

2. Melon Grade A Pallets

Pallets in slightly rougher shape, with some discoloration and minor damage, are classified as Melon Grade pallets.

These pallets can be made of pine or hardwood, but they should not have any metal plates or obvious repairs. Melon Grade pallets are also referred to as 1B pallets.

3. Regular Grade A Pallets

1R pallets, also known as Regular grade, are the most common type of GMA Grade A pallet. While they are still in fairly good shape, these pallets differ from Premium A and Melon grade in that they may have some stringer repairs with metal plates, fasteners or staples.

The boards and stringers of Regular grade pallets are typically made of pine and may not meet the GMA grade standard board configuration or thickness specifications.

Grade B Pallets

Pallets are classified as Grade B pallets if they show evidence of more extensive use and damage. They may be worn and discolored or have previous stringer repairs with either metal plates and fasteners or supporting blocks.

Warehousing and shipping applications use Grade B pallets as an alternative to more expensive products because the appearance of the pallets doesn’t matter as much in these situations.

Pallet industry recyclers will further classify Grade B pallets into subcategories according to the number of repair patches the pallets have per forklift cavity and the types of repairs completed.

Repairs made with metal plates and fasteners tend to be more secure and streamlined. These types of repairs may only indicate small amounts of damage, whereas repairs made using blocks to support stringers indicate more structurally compromising damage.

1. Premium Grade B Pallets

Pallets with only one repair per cavity may be classified as Premium B or #2 High Grade. These repairs should make the previously damaged pallets sturdy and stable enough to use without issue.

2. Standard Grade B Pallets

If a pallet has two or more repairs per forklift cavity, it will be classified as Standard B or #2 Regular grade. The standard Grade B pallet category is the lowest standard GMA grade offered by many manufacturers.

Nonstandard Pallets

Pallets that do not meet the standards for Grade A or B are considered Grade C. These pallets have poor appearances and many repairs. They may not be in good structural shape despite a number of repairs.

Many manufacturers do not offer Grade C pallets because they are more likely to fail than other classifications. As a result, their use can be dangerous for workers as well as the materials being transported.

Additionally, many manufacturers and recyclers offer specialty-grade food pallets that may not meet GMA specifications. The best way to shop with confidence is to determine your requirements in advance and work with a knowledgeable supplier who can help you make an informed choice.

Wood vs. Plastic Pallets

While these GMA standards and grades focus on wooden pallets, many plastic pallets also meet the basic GMA pallet dimensions specifications. Plastic pallets are gaining popularity in the food and beverage industry because they offer several unique advantages over pallets made of wood.

Though wood pallets are often a cheaper option, they have a much shorter lifespan and do not perform as well. Investing in plastic GMA pallets may cost more initially, but they will pay for themselves within a few trips since they do not need to be repaired or replaced as frequently.

Browse Our Plastic Pallet Selection

Learn More About Our Plastic Pallet Options

At Polymer Solutions International, Inc., we manufacture a range of material handling products that are built for long-term productivity and easy cleaning.

Keep browsing our website to learn more about what we offer when it comes to plastic pallets. You can also start a live chat session, contact us online or call us directly at 610-325-7500 for assistance.